Application

Coarse screen Hydrorax are used as continuous mechanical pre-treatment of wastewater on municipal wastewater treatment plants.

Technical description

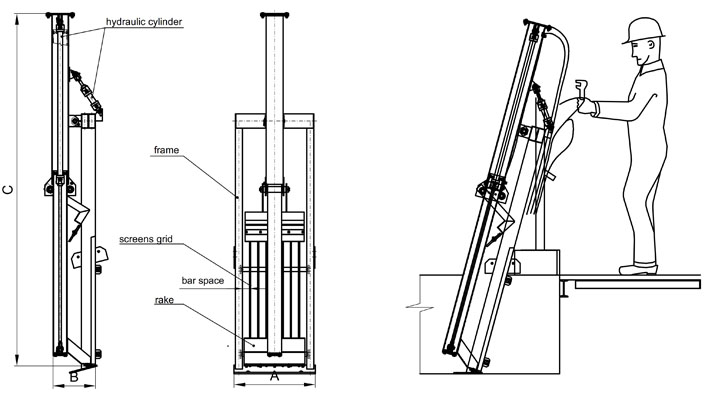

Coarse screen Hydrorax composes of:

- support frame

- rake

- screen grid

- hydraulic cylinders

- hydraulic unit

- hoses

- channel for rakings

- automation switchboard

Wastewater flows onto the coarse screen through a concrete channel. The support frame of the screen is fixed to the bottom and walls of the concrete channel. Debris larger than bar space of the screen are caught on the screen grid. Wastewater along with smaller debris continues for further treatment step. The screen grid is wiped with rake that transports the caught debris in a channel for rakings or into rakings press. Motion of the rakes is ensured by a pair of hydraulic cylinders. The hydraulic cylinders are actuated by hydraulic unit. The equipment works in a full automatic mode in dependance on the wastewater level in front of the screen.

|

|

|

| Coarse screen Hydrorax | Coarse screen Hydrorax |

Material workmanship

Support frame, the rake and the screen grid are made of stainless austenitic chromium-nickel steel grade 1.4301. Wiping and screen strips are made of PE 1000 polyethylene.

Model range

The coarse screen Hydrorax are made in seven models with designation H10, H20, H30, H40, H50, H60, H70 with various dimmension of the bar space of the screen grid. Dimensions of the machine are dependent on the concrete channel width and requested flow.

| Typ | Bar space [mm] |

|---|---|

| Hydrorax H 10 | 10 |

| Hydrorax H 20 | 20 |

| Hydrorax H 30 | 30 |

| Hydrorax H 40 | 40 |

| Hydrorax H 50 | 50 |

| Hydrorax H 60 | 60 |

| Hydrorax H 70 | 70 |

|

| drawing of coarse screen Hydrorax |