Application

Manual lifting mechanisms (small cranes) are designed for various weights lifting – e.g. pumps, mixers, rack baskets and other equipment which is used at waste water treatment plants or pumping stations.

Technical description

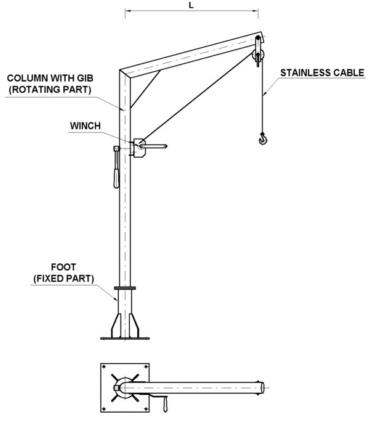

Main supporting elements of lifting mechanism structure are column, gib, hung of pulley and two pivots (one for fixing the hung in gib and second for fixing the pulley in the hung). For weights lifting and lowering is used manual cable winch with stainless cable. Column of the lifting mechanism is inserted into footstep bearing (foot), which enables rotation of small crane (small crane is for easy rotation equipped with bar with handle).

Material workmanship

Column, gib and foot are made from steel 11 353, hung of pulley from steel 11 373 and pivots are made from steel 11 500. Structure is hot galvanized.

Installation

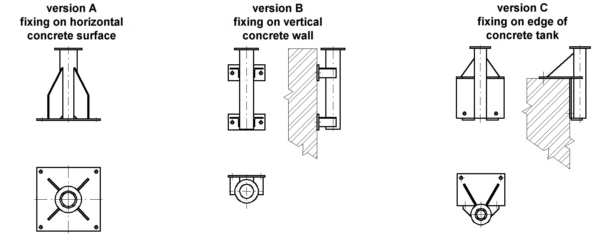

Foot can be fixed according to demands either on horizontal concrete surface or vertical concrete surface (e.g. wall of tank) or on edge of concrete wall. Anchor material is always included in supply.

Lifting capacity and radius

Small cranes are produced in wide range of lifting capacities with various radius according to demands of a customer.

Standard lifting capacity range: 50 kg, 100 kg, 150 kg, 200 kg, 250 kg, 300 kg, 350 kg

Standard radius range: 0,8 m; 0,9 m; 1 m; 1,1 m; 1,2 m; 1,5 m; 1,7 m

Based on request of the customer, the gib can have more holes for fixing the hung of pulley, so that the radius can be changed. According to wish of the customer it is possible to produce also small cranes with other lifting capacity and radius than the standard range is.