top quality and affordably priced stainless small waste water treatment plants for 75 - 150 PT

Package waste water treatment plants (abbreviation WWTP) are optimal solution in areas where is no sewerage, because in comparison with costs on cesspool emptying, the operation costs of small waste water treatment plants are minimal. Treated water from small WWTP can be discharged directly into receiving water.

Package waste water treatment plants Stainless Cleaner have following features:

- high treatment efficiency (circa 90 - 98 %)

- low operation costs

- silent operation without bad smell

- high operation reliability at minimal maintenance

- long durability

- precise workmanship

Application

Waste water treatment plants Stainless Cleaner type SC 75, SC 100 and SC 150, are designed for treatment of sewage water from block of flats, workrooms, restaurants, hotels, parts of villages, mobile workingsites, etc. They enable treatment of waste water from toilettes, bathrooms, washing machines, dishwashers, etc.

Description of waste water treatment technology

Waste water treatment is based on biological principle. Microorganisms, which are necessary for treatment process, naturally cultivate in WWTP. Sewage water represents for microorganism nutrients and owing to the fact that into WWTP is brought air from the blower, the microorganism have in WWTP optimal conditions for life and they reproduce there themselves. Since WWTP operation startup, it lasts approximately 3 – 8 weeks, till the microorganisms reproduce to necessary population. At bigger WWTPs, this process is accelerated via inoculation with sludge taken from other well-functioning WWTP.

All wastewater from a household (i.e. water from WC, kitchen, washing machine, dishwasher, bath, shower) first flows into area of mechanical pre-treatment – perforated aerated inflow basket. The inflow basket serves for catching raw indecomposable impurities, e.g. if by mistake into canalization gets swab or some plastic object. Because the inflow basket is aerated, inside it the impurities are intensively disintegrated and all waste from WC including toilet paper disintegrates inside it and through holes of the basket passes to next part of WWTP.

Mechanically pre-treated waste water flows into hydraulically mixed area of denitrification, where nitrogenous pollution is eliminated. From the denitrification the waste water flows into aerated area of activation. In activation tank organic pollution is eliminated and ammonia nitrogen nitrifies. Mixture of activated sludge and treated water further flows into vertical settlement tank, where treated water separates from activated sludge. Treated water flows through serrated spillway into outflow pipeline. Sludge, which settles on the bottom of settlement tank is pumped via recirculation air-lift pump back into denitrification.

For ensuring aeration of activation, for sludge recirculation, denitrification mixing and inflow basket aeration serves a blower, which is placed outside the WWTP, in most cases in garage, technical room or in some concrete or wooden shelter. Operation of blower is controlled via timer.

Material workmanship

Waste water treatment plants SC 75 – SC 150 are made from first-class stainless austenitic chromium-nickel-molybdenum steel - grade 1.4571 (AISI 316Ti) or 1.4404 (AISI 316L), which is for its extreme corrosion resistance used above all in chemical industry. From the point of view of using this material for package wastewater treatment plants it is necessary to highlight, except from high corrosion resistance, also its huge mechanical robustness and ability to resist without problems any low temperatures (high freeze resistance). Using this unique material it is reached high product lifetime.

Structural design

Waste water treatment plants SC 4 – SC 50 are designed in such way to reach maximal treatment efficiency, operation reliability, easy service, economical operation and minimal maintenance. These characteristics are reached owing to optimal arrangement, shape and size of single technological parts of WWTP, next owing to enough sizing of internal technological parts (air-lift pumps, air distributors) and last but not least owing to the fact that aeration and all mechanical processes in WWTP (recirculation, mixing) ensures the air, whose source is blower. Small WWTPs Stainless Cleaner don’t have any mechanical rotation parts, which are source of often malfunctions and reason of high energy consumption.

Installation

Before installing the WWTP, it is necessary to make the pit, concrete basement on the bottom of the pit, lay down inflow and outflow canalization and make excavation for air pipeline from the blower to WWTP. The installation itself lasts only several hours. During installation the WWTP is placed into the pit on concrete plate, inflow and outflow of WWTP is connected to canalization (we connect always pipeline 1 m before WWTP and 1 m behind WWTP), air pipeline from blower to WWTP is laid down, WWTP is filled with water, valves are adjusted, WWTP is tested and the operator is trained.

Covering of WWTP

Covering of WWTP is solved via elegant, practical and resistant cover. This two-piece cover is equipped with hinges and is lockable to prohibit access into WWTP. Cover is made from water-resisting exterior plywood and is margined by stainless sheet metal.

Parameters of treated water

When designed values of inlet material and hydraulic load of WWTPs SC 4 - SC 50 are kept, then quality of treated water reaches following average values:

| BOD5 | 15 mg/l |

| CODCr | 75 mg/l |

| SS | 25 mg/l |

Experience has proven that when WWTP is properly operated according to instructions in operation manual, even single-digit values of BOD5 can be reached.

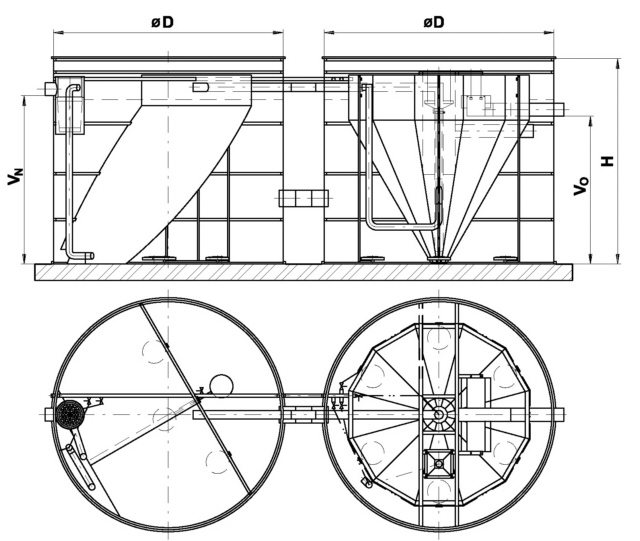

Technical parameters of WWTP SC 75 – SC 100

| Type | Number of connected inhabitants |

Q (m3/d) |

BOD5 (kg/d) |

D (mm) |

H (mm) |

VN (mm) |

VO (mm) |

Weight (kg) |

Energy consumption (kWh/d) |

|---|---|---|---|---|---|---|---|---|---|

| SC 75 | 56 - 79 | 11,3 | 4,5 | 2 x 2600 | 2350 | 1800 | 1550 | 800 | 9,00 |

| SC 100 | 80 - 109 | 15,0 | 6,0 | 2 x 2800 | 2500 | 2050 | 1800 | 1100 | 11,10 |

|

| Drawing of WWTP SC 75 a SC 100 |

|

|

|

| transportation of WWTP SC 100 | example of installed WWTP SC 100 |

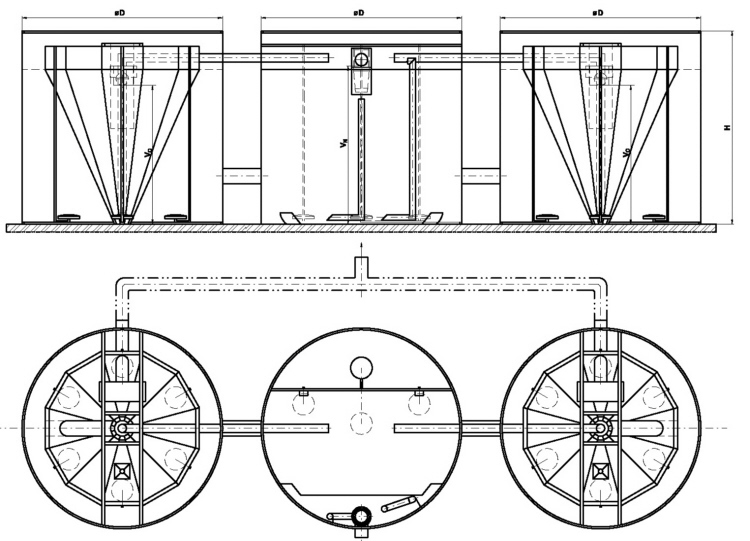

Technical parameters of WWTP SC 150

| Typ | Number of connected inhabitants |

Q (m3/d) |

BOD5 (kg/d) |

D (mm) |

H (mm) |

VN (mm) |

VO (mm) |

Weight (kg) |

Energy consumption (kWh/d) |

|---|---|---|---|---|---|---|---|---|---|

| SC 150 | 110 - 160 | 22,5 | 9,0 | 3 x 2800 | 2500 | 2050 | 1800 | 1700 | 13,20 |

|

| Drawing of SC 150 |

|

| WWTP SC 150 before expedition |