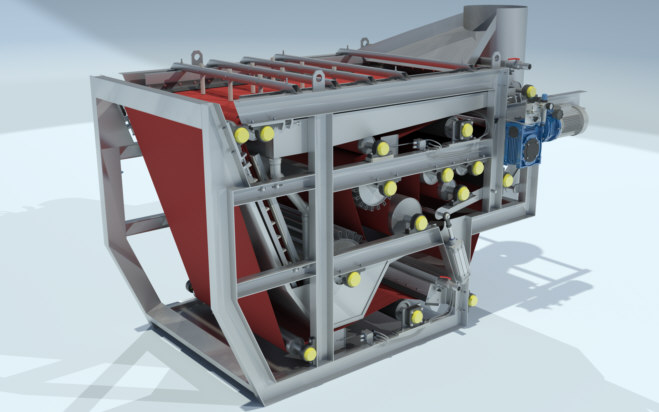

Application

Belt filter press Compacteron brings an efficient way of sludge dewatering at municipal waste water treatment plants.

|

| Compacteron C8 |

Technical description

Belt press Compacteron is composed of:

- supporting frame

- inflow homogenization tank

- system of cylinders

- belt filters

- unit for flocculant preparation and dosing

- sludge pump

- high pressure pump for wash water

- two sets of wash jets

- electromotor with gearbox and variator

- air compressor

- tubs for filtrated water

- chute for dewatered sludge

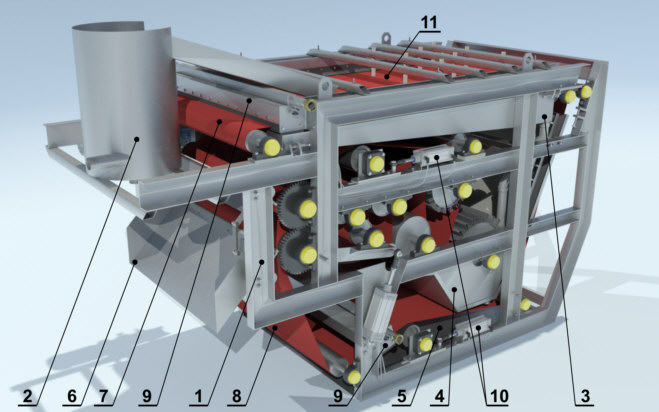

After mixing with flocculant the sludge is brought tangentially into homogenization tank (2), from where it is evenly spread onto the belt in the zone of gravitation dewatering (11). Filtrated water from this zone outflows into upper tub (3) and further into middle (4) and bottom tub (5). The sludge continues into a zone of forced dewatering as it is brough between two belt filters (7, 8) that go through the system of cylinders, thus inflicting intense dewatering. Filtrate is taken off through middle (4) and bottom tub (5) into denitrification or pumping station. The filtrated sludge is removed from the belts using scraper bars and falls through a chute (6) onto a belt conveyor which transports the sludge cake into a storage container. The belts are cleansed by water from wash jets (9) with pressure of cca 6 bar. The system of wash jets is fastened with rapid couplings so it can be quickly detached and cleaned when needed. The drive cylinders are rubbered. The drive cylinders are rotated by electromotor with gearbox and variator thus enabling adjustment of belt velocity according to characteristic of sludge. Centering of the belts is ensured by pneumatic mechanisms (10).

|

| 1 - supporting frame, 2 - inflow homogenization tank,

3 - upper tub, 4 - middle tub, 5 - bottom tub, 6 - chute, 7 - upper belt, 8 - bottom belt, 9 - belts wash, 10 - centering of belts, 11 - zone of gravitation dewatering |

Material workmanship

Supporting frame, system of cylinders, inflow homogenization tank, tubs, chute and unit for flocculant preparation and dosing are made of stainless austenitic chromium-nickel steel grade 1.4301.

Model range

The belt filter presses Compacteron are made in four types marked C2, C3, C6 a C8 with various performance and belt width.

| Type | Belt width [mm] |

Q [m3/h] |

|---|---|---|

| Compacteron C2 | 600 | 0,5 - 3 |

| Compacteron C3 | 600 | 2 - 4 |

| Compacteron C6 | 800 | 3 - 8 |

| Compacteron C8 | 1000 | 6 - 10 |

| Compacteron C10 | 1250 | 8 - 13 |

Beltpress Compacteron C6 in operation |