Application

Screw screen ScreenHelix with integrated press for screenings serves as mechanical pretreatment at wastewater treatment plants both with gravitational inflow and inflow from pumping station. They can be installed into stainless tub or directly into concrete channel. They are designed to be placed inside the building.

Technical description

Screw screen ScreenHelix consists of:

- stainless tub (if it is not installed directly into concrete channel)

- shaft with worm, which is equipped with brushes,

- body tube, where in its bottom part is sieve,

- exit chute for screenings,

- gearbox with electromotor

|

|

|

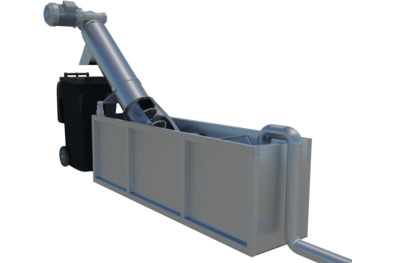

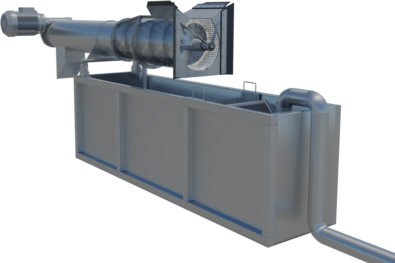

| Screw screen SH300 in stainless tub - functional position | Screw screen SH300 in stainless tub - servicing position |

Waste water flows gravitationaly into concrete channel or is pumped into stainless tub, where is placed body tube with worm. In bottom part of body tube is located sieve, where suspended solids with bigger dimension than is dimension of sieve's holes, are caught. In pre-set time intervals the self-cleaning cycle is switched on and during this cycle, when worm rotates, catched suspended solids move up and brushes fixed on worm clean the sieve. The device is equipped with level sensor. When water level before the sieve rises to a certain height, the self-cleaning cycle is switched on even out of pre-set time interval. For easy maintenance the screw scren is equipped with tipping screw mechanism, with which you can tip the whole body tube into horizontal position. Inflow into wastewater treatment plant is in this position protected by insertion of screen grate into tub or concrete channel before the screw screen.

Material workmanship

All components of screw screen ScreenHelix, which comes into contact with waste water are made of stainless austenitic chromium-nickel steel 1.4301. Fibres of brushes are made of polyamide.

Model range

The device is made in four sizes. According to customer's wish it can be produced larger models.

| Type | Power input [kW] |

Flow Qmax [l/s] |

Holes [mm] |

Channel width x depth [mm] |

|---|---|---|---|---|

| SH 300 | 1,1 | 30 | 6 x 26 | 400 x 600 |

| SH 400 | 1,1 | 40 | 6 x 26 | 500 x 700 |

| SH 500 | 1,5 | 50 | 6 x 26 | 600 x 800 |

| SH 600 | 1,5 | 60 | 6 x 26 | 700 x 900 |