Application

Sludge dewatering device Stainless Sacker serves for dewatering primary and stabilized activated or mixed sludge. The principle of dewatering is based on dosing polymeric flocculant into sludge, which after mixing with flocculant agglomerates and subsequently is filtred through filtration sacks. Thickened sludge remains inside sacks and the filtrate flows back to denitrification area of wastewater treatment plant. The device is very simple, reliable in operation, financially undemanding and it is used at all wastewater treatment plants, where it is necessary to solve sludge disposal cheaply and effectively. Produced thickened sludge has twenty times smaller volume after 12 hours sedimentation in comparison with unthickened state.

|

|

|

| Stainless Sacker S3 device | Stainless Sacker S4 device |

Technical description

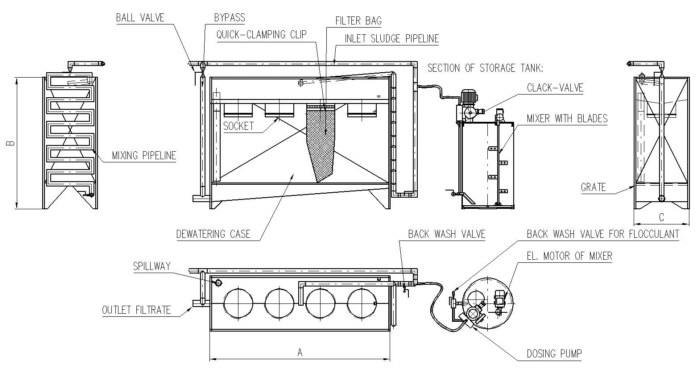

The device consists of dewatering cabinet with sockets for clamping filtration sacks via quick-clamping clips, further of polymeric flocculant dosing device, inlet sludge pipeline, sludge pump and mixing pipeline. The sludge is pumped via pump from the sludge tank through mixing pipeline into dewatering case. Polymeric flocculant is dosed into mixing pipeline and it causes that sludge begins to agglomerate into flakes and this agglomerated sludge is led into dewatering case and through sockets goes into filtration sacks. Filtration sacks stand on grate through which the filtrate flows back to denitrification area of wastewater treatment plant. The case is equipped with probe to guard water level and next is equipped with spillway in case of failure. The dosing device of polymeric flocculant include storage tank with mixer and dosing pump. Operation of device and end of dewatering cycle is signalized via light on switchboard.

|

| drawing of Stainless Sacker device |

Material Workmanship

Dewatering cabinet, storage tank for flocculant, shaft of mixer with blades and quick-clamping clips are made from stainless chromium-nickel steel 1.4301 grade. Inlet and mixing pipelines are made from polypropylene.

Model range

| Type | No. of sacks | Amount of processed sludge [m3] |

WWTP maximal capacity |

|---|---|---|---|

| S3 | 3 | 3 - 4,5 | 500 EO |

| S4 | 4 | 4 - 6 | 1000 EO |

| S6 | 6 | 6 - 9 | 1500 EO |

|

|

|

| Stainless Sacker S3 device operating | sludge dewatered after 12 hours |