Application

Rotary drum sieve is used for continual mechanical pretreatment of waste water at municipal waste water treatment plants.

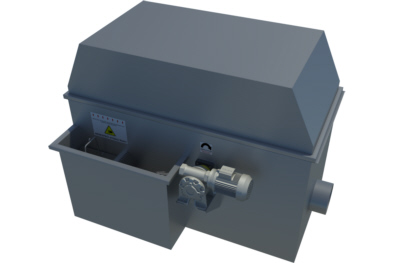

Technical description - rotary drum sieve for pressure sewerage

Rotary drum sieve consists of:

- inflow socket

- curved sieve

- rotating wipers

- outlet chute for rackings offtake

- tank with offtake of pretreated water

- gear-box with electromotor

- cover

- frame

- container for rackings

|

| rotary drum sieve for pressure sewerage |

Wastewater flows through inflow socket into tank, where the sieve, shaped as element of cylindrical surface, is fixed. Suspended solids bigger than holes of sieve are separated on the sieve. Wastewater together with small impurities gravitationally flows down under sieve and is led away through outflow pipeline for next biological treatment. Material caught on sieve is lifted up via four rotating wipers, fixed on shaft and through outlet chute rackings fall into container. Rotation of wipers is ensured via electromotor with gear-box. Whole tank is seated on frame and equipped with removable cover.

Technical description - rotary drum sieve for gravitational sewerage

Rotary drum sieve consists of:

- inflow socket

- curved sieve

- tank with offtake of pretreated water

- rotating wipers

- perforated aerated and removable bin for rackings

- by-pass tub with manually wiped screen

- gear-box with electromotor

- cover

|

| Rotary drum sieve for gravitational sewerage |

Wastewater flows through inflow socket into tank, where the sieve, shaped as element of cylindrical surface, is fixed. Suspended solids bigger than holes of sieve are separated on the sieve. Wastewater together with small impurities gravitationally flows down under sieve, where it can freely outflow into denitrification or it can be brought by pipeline for further biological treatment. Material caught on sieve is lifted up into perforated bin via two rotating wipers, fixed on a shaft. The perforated bin is equipped with a lifting mechanism for easy manipulation. The perforated bin is aerated, thus ensuring perfect rinsing of the caught material and its partial disintegration. Rotation of wipers is ensured via electromotor with gear-box. In case of power shortage the device is equipped with by-pass tub with manually wiped screen. Whole device is equipped with removable cover.

Material workmanship

All components of rotary drum sieve, which are in contact with wastewater are made of stainless austenitic chromium-nickel steel grade 1.4301. Fibers of wipers are made of polyamide.

Model range

The device is made in four types, named RBS 600x750, RBS 600x1000, RBS 1100x750 and RBS 1100x1000 with different size of sieve and flow.

| Typ | Prýtok Qmax [l/s] |

|---|---|

| RBS 600x750 | 7 |

| RBS 600x1000 | 12 |

| RBS 1100x750 | 20 |

| RBS 1100x1000 | 30 |