Application

Slide gates with electric drive and check gates with manual handling are

designed for opening, closing or regulation of water flow in open canals.

They are used above all in water and wastewater treatment plants, irrigation

systems, where they enable easy and quick closing of inlet or outlet canals,

in automation of water and wastewater treatment plants operation and in other

plants with water distribution in open canals.

Technical Description

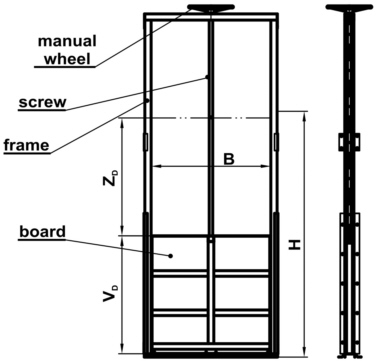

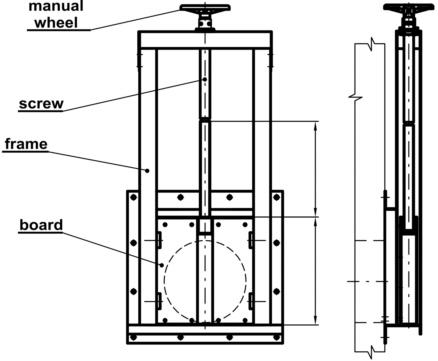

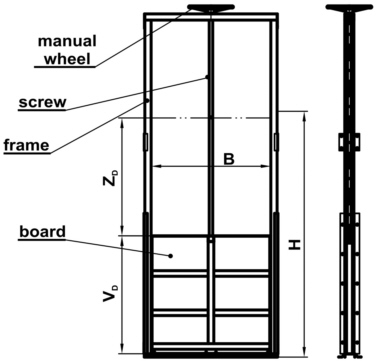

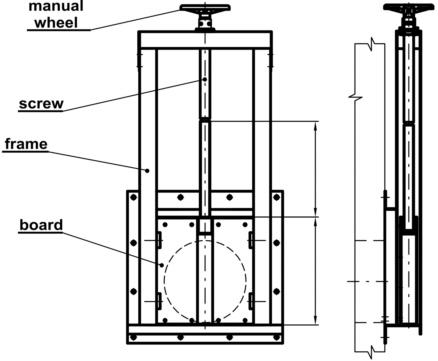

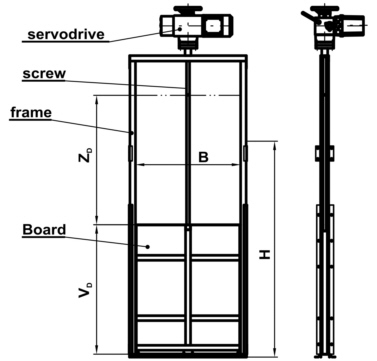

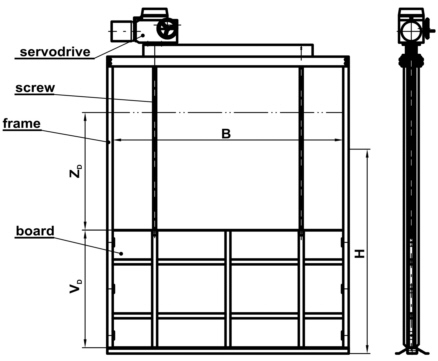

Supporting part of the slide gates is frame, which is adapted for installing

and concreting its outer parts into grooves in walls of canal. Inner

surfaces are provided with sealed guide of check gate’s board.

|

|

|

| single-spindle slide gate channel-mounted with manual control |

|

single-spindle slide gate channel-mounted four-side sealing with manual control |

|

|

|

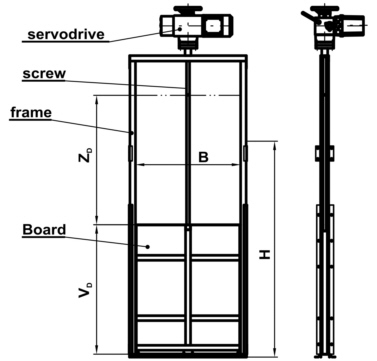

| single-spindle slide gate channel-mounted with electric drive |

|

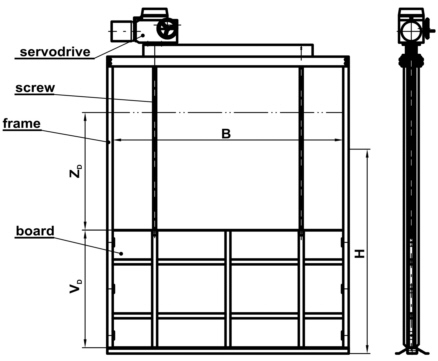

double-spindle slide gate channel-mounted with electric drive |

Vertical motion of the board is solved via motion screw, whose rotation is

performed manually or by electromotor. Servomotors MODACT or SCHIEBEL are

used as a drive unit. Vertical shift of check gate’s board can be controlled

remotely from control workplace. Limiting positions of check gate’s

board are defined by limit switches, which switch off the electromotor in

limiting positions. Servomotors are protected against overload via torque

switch-off unit, which disconnects electromotor from electrical network,

when torque on output shaft exceeds preset limit value. Servodrives are

equiped even with wheel for manual handling.

Material workmanship

Check gates are made from corrosion-resisting austenitic Cr-Ni steel 1.4301 (according to DIN or European standards).

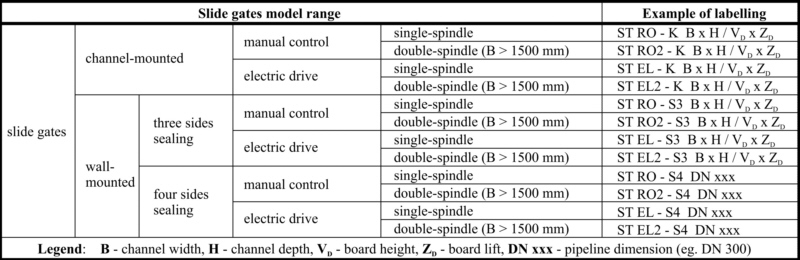

Model range